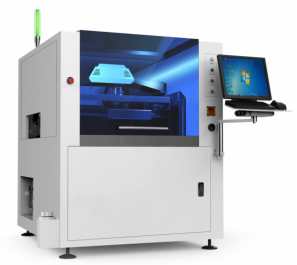

he preferred model with high cost performance

l Single section rail shorts the length of transport rail in the printing area, and increases buffer zone at the position of pcb in and out to improve the production efficiency of the whole line.

l The printing area and buffer zone operate independently, printing and PCB in and out at the same time, saving time or the production of high speed products.

Specifications

Process parameter | Description |

Printing accuracy | ≥2 Cpk@±25μm@,6σ |

Repeat positioning accuracy | ≥2 Cpk@±10μm@,6σ |

Cycle time | 7s |

Max. printing area | 400mm x340mm |

Stencil size | 470mm x 370mm~737mm x 737mm |

Stencil thickness | 25mm - 40mm |

Squeegee pressure | 0kg - 10kg |

Printing speed | 1mm/sec - 200mm/sec |

Printing clearance | 0mm - 20mm |

Demoulding parameters | speed:0.1 - 20mm/s distance:0mm - 3mm |

Demoulding method | Optional squeegee up first or demoulding first |

For material | Solder paste, ink, Ag paste |

Transporting PCB | Description |

Belt type | U-type gear belt, front rail fixed |

ESD compatibility | black transportation belt and rail surface resistivity>110Ω |

Width adjustment | Programable control the back rail |

Transporting direction | L→R,L→L,R→L,R→R |

Min. PCB size | 50mm (X) x 50mm (Y) |

Max. PCB size | 400mm (X) x340mm (Y), |

PCB thickness | 0.4mm - 5 mm |

PCB weight | ≤3kg |

PCB warping | ≤1% of diagonal |

PCB fixing | Flex edge clamping |

Clearance under PCB | ≤18mm |

Vision system | Description |

Multi-function image process syestem | Mark point software measurement, secondary positioning, component recognition function, digital camera: 1.3 million pixels, camera depth of field: 2mm, FOV:10X8mm |

The image positioning system | automatically aligns and teaches, and recognizes the minimum mark point of 0.1 mm |

Mark quantity | 2 or 4 |

Mark type | square, circle, triangle, cross, user - defined type |

Mark size | 0.1mm ~ 3mm |

Mark position | Any position on PCB |

Mark position compensation | Automatic optical adjustment and search of mark |

Light source of camera | Manual adjustment |

2D inspection | With the system |

Software and communication | Description |

Intelligent software backup module | database automatic backup, software upgrade will not be lost |

Maintenance warning function | machine screw, slider, motor and other automatic maintenance information prompt |

The intelligent module of printing parameters | selects the type of production PCB and automatically gives the optimal parameter setting |

The automatic solder paste recovery system | controls the squeegee to recover the solder paste to the printing stroke with timing or frequency |

Standard configration | Description |

Frame | formed as a whole |

Control | 3 pcs move control cards |

Operation system | Windows XP |

Interface | 17 inch DELL display, keyboard, mouse,V2 software |

Squeegee | straight screw rod/single point suspension squeegee |

Squeegee pressure control | Software setting |

Stencil auto positioning | The stencil is placed into the support frame, and the squeegee head automatically realizes the stencil plate positioning |

Supporting positioning | Supporting block with the same height, pin, plate |

Stencil cleaning system | multi-size wiping paper universal, lower paper consumption, cleaner control module |

Machine interface for line | SEMI Input/Output 4 core international standard interface |

Machine communication interface | RJ-45LAN(net) and USB2 |

Warning | three-color intelligent LED warning light |

High precision platform | platform adopts annealing technology + knife fast milling method to reduce the residual metal stress in the platform, which is not easy to deform after long-term use and ensures the accuracy. |

Rapidly platform adjustment system | knob manual quick adjustment of platform height, X,Y, and θaxes are independently adjustment |

Intelligent compensation platform | automatic stop pcb device + automatic pcb positioning + left in left out, left in right out, right in right out, right in left out |

Manual | Operator manual, installation |

Dimension | 1140(L)X1360(W)X1505(H)mm |

Weight | 1100kg |

Facility | Description |

Power | Voltage:220V,±10%,1 phase, 50/60Hz |

Power comsuption | 2kw |

Air | 0.45- 0.6kg/cm² |

Temperature on site | 25±3℃ |

Humidity | Relative humidity: 30% - 70% |

Certification | Description |

CE | 98/37/EC,89/336/EEC,73/23/EEC |

Noise level | Less than 87dB |