Pemtron Automated Optical Inspection

Shadow-free High-speed Inspection and Measurement

EAGLE 8-projector 3D AOI system is adopted to inspect 100% PCB board in 2D & 3D concurrently in all FOV areas, ensuring the shadow-free optical inspection and low false-call rates, while keeping the system functionality highly flexible.

High-speed Inspection Technology

EAGLES High Speed Option inspects in 40.5cm sq. per sec. by utilizing an advanced network of more robust CPU, controller boards and our proprietary developed 9MP 15um 150fps camera with telecentric lens.

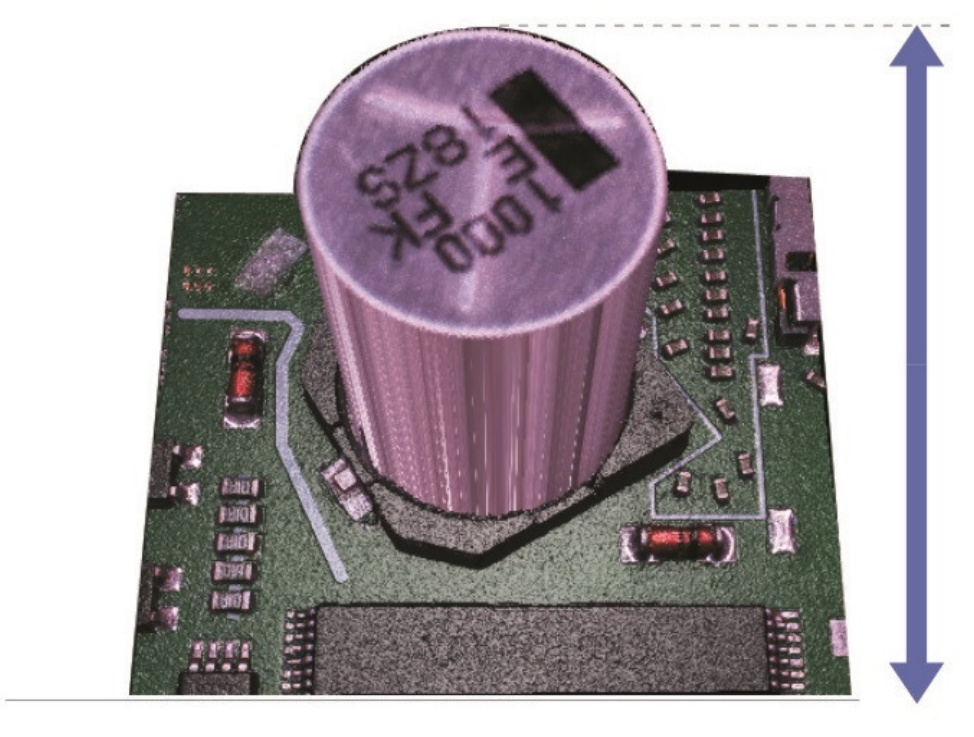

High Component Inspection Technology

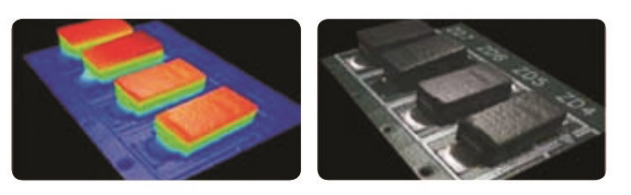

EAGLES optional new 10-Way Projection Technology provides an industry first 25 mm component height inspection in 100% 3D.

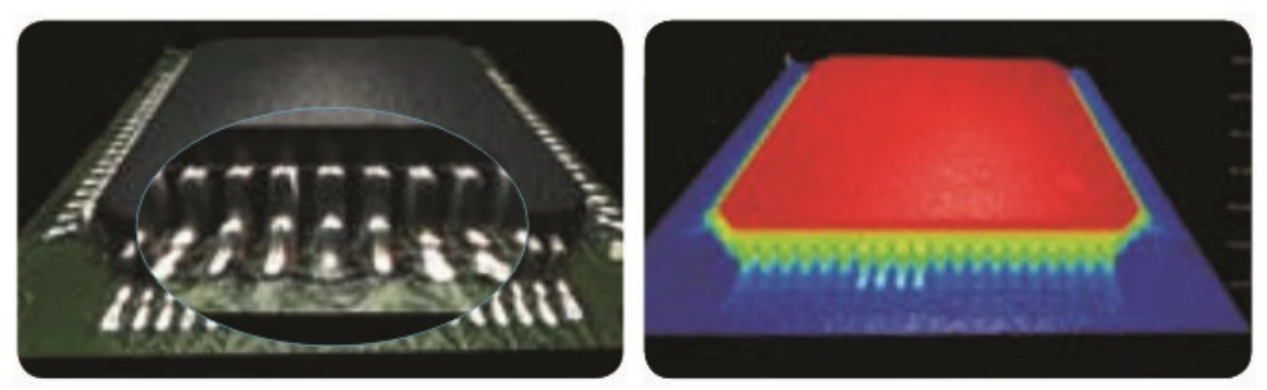

3D Automatic Optical Inspection System

Shadow-free 3D technology eliminates the shadow caused by highly populated PCBs and high components.

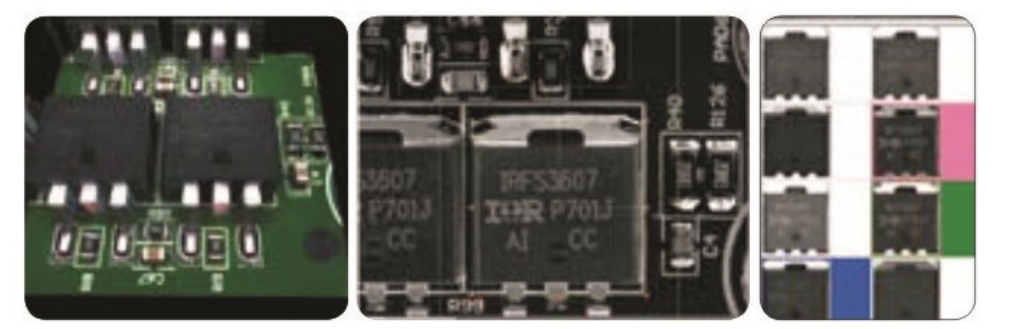

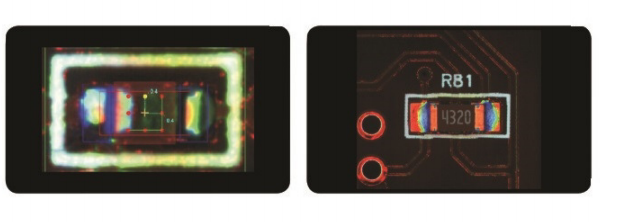

Optical Character Recognition

Color and pattern algorithms are adopted to recognize component part name, where the OCR font can be added or modified to optimize inspection condition.

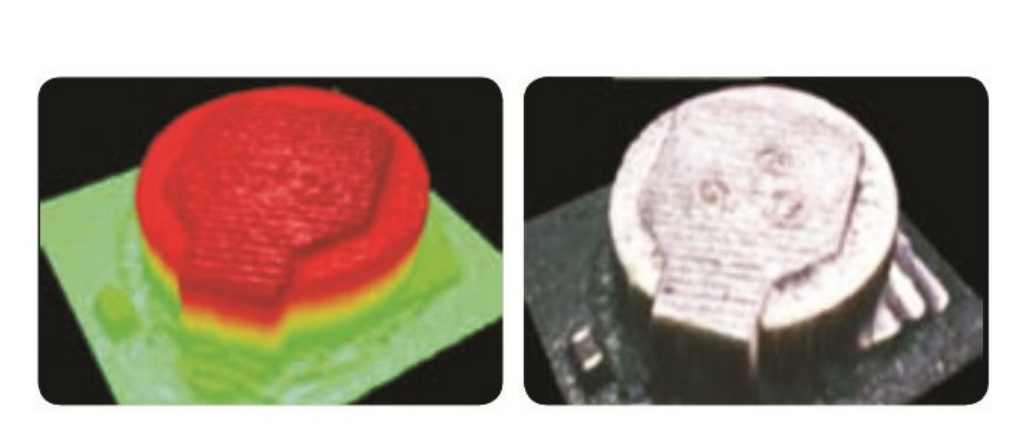

3D Lead Inspection

3D measurement algorithms is adopted to measure lead height and volume of solder, where true-color 3D images are presented.

3D Solder & Height Measurement

By utilizing advanced 3D technology, EAGLE 3D AOI is capable of conducting more inspection than the traditional 2D AOI, where the inspection of height and volume of the solder paste, and of the co-planarity of each component are added, enhancing the defect detection capability.

2D RGB Algorithm

The adoption of the 2D RGB image enables operator to easily identify the defections such as empty solder and lead warping.

Simple Programming (Automatically Guiding)

Advanced 3D image processing technology can accurately identify and measure components of any geometric shape and automatically update them to the standard component library, which is simple to program and fast to debug.

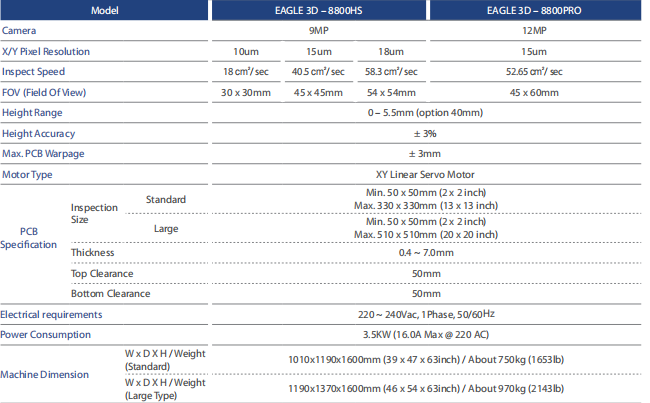

Technical Parameters